Stochastic loads, varying speeds, interfaces with complex stiffness profiles: the service life of rolling bearings in wind turbines depends on numerous influences. With the Large Bearing Laboratory (LBL), Fraunhofer IWES has unique methodological expertise as well as testing and research infrastructure for increasing the reliability of bearings. IWES develops and realizes validation strategies, test concepts, test rigs, measurement methods, test campaigns, CAE models and much more to ensure the product characteristics of mechanical wind turbine drive trains. To ensure the structural stability of the turbine, the design and manufacturing of the wind turbine support structures – e.g., tower, foundations and necessary attachments – must be optimized in line with the increasing operating loads. IWES is developing proposals to reduce the economic and technical risks of future support structures.

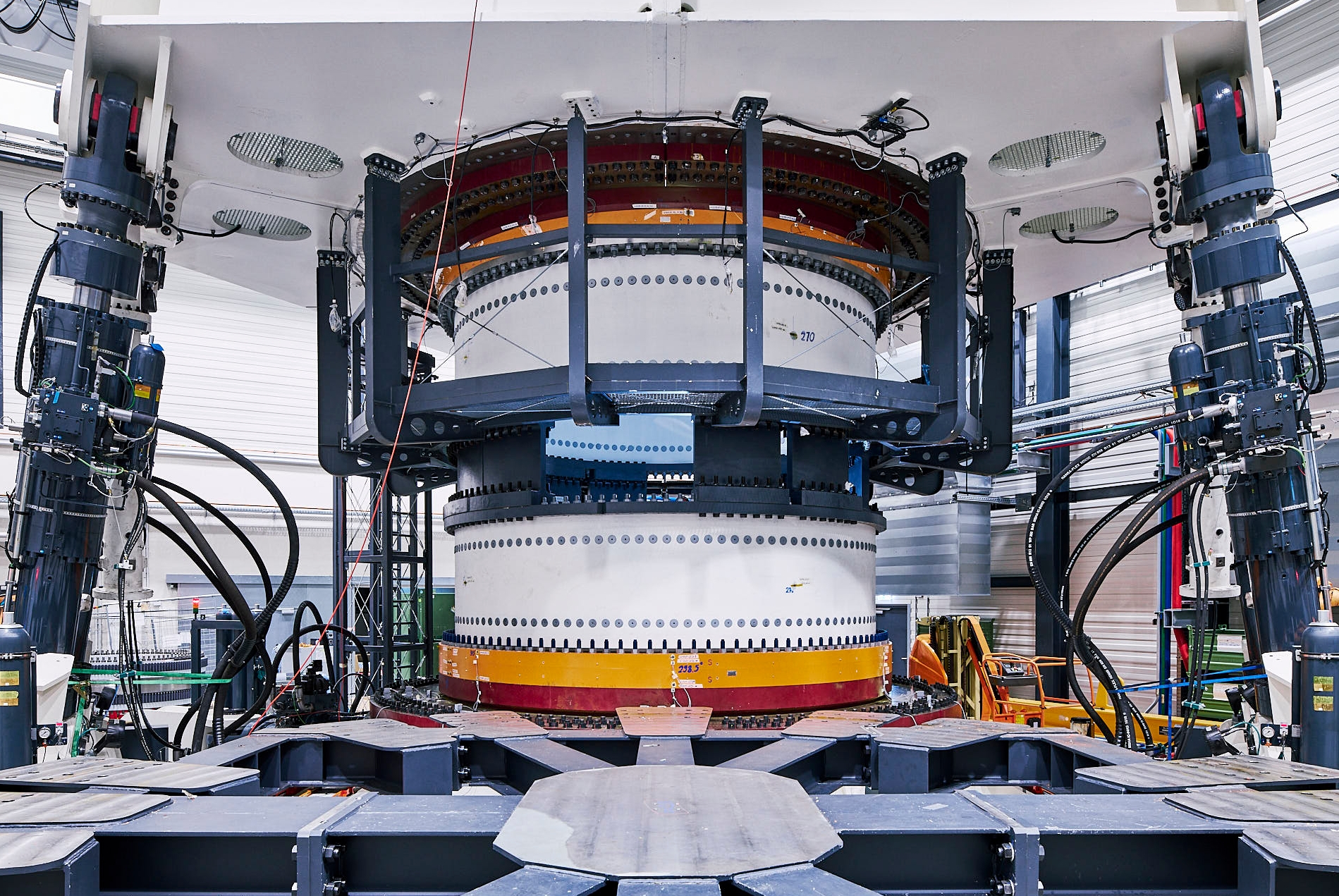

For large-scale wind turbine nacelle testing, IWES has a test rig, the Dynamic Nacelle Laboratory (DyNaLab), which is the only one of its kind in the whole world. It contains a powerful load application system (LAS), which is equipped as a hexapod with a large moment bearing and offers a realistic test environment in the multi-megawatt range for meaningful laboratory tests.

Failures of wind turbine drive trains are one of the main causes of downtimes. Virtual tests using simulation models and validated measurement data allow loads to be identified as early as during the development process. IWES has exceptional experience in the collection and processing of corresponding measurement data.

more info