Reliability, monitoring, and yield analysis: How IWES significantly boosts the efficiency of offshore wind farms

In the course of several publicly funded projects, Fraunhofer IWES in collaboration with partners has been able to build up a unique field database of failure and operating data from wind turbines worldwide. This collection facilitates boosting the reliability of turbine components, reducing costs and risks, performing OPEX modeling and cost-benefit analyses, and testing methods for early fault detection. In addition, IWES runs computational fluid dynamics (CFD) simulations for the protection of flexible rotor blades, which make it possible to identify and reduce the blades’ susceptibility to vibrations – for example when the turbine is at a standstill or in trundle mode. For highly efficient project and risk management, IWES also offers project plan and weather risk analyses in order to assess potential risks at an early stage. IWES evaluates the performance and efficiency of existing offshore wind farms by means of post-construction and performance analyses. The portfolio also encompasses optimized maintenance concepts, the assessment of existing concepts, and the optimization of the O&M logistics, in order to develop tailored, cost-efficient solutions.

Our areas of expertise

Technical reliability

Better understanding and improvement of O&M activities

Fraunhofer IWES boasts many years of success in publicly funded projects on the topics of the reliability of power converters, root cause analysis, condition monitoring, and the digitalization of O&M data. In addition, IWES also has considerable experience in O&M modeling, cost-benefit analysis, and the optimization of O&M strategies on the basis of field data.

Further information in the data sheet: Understanding and improving O&M activities

More reliable wind turbine components and better OPEX modeling input thanks to unrivaled collection of field data

Many years of research have enabled IWES to build up extensive expertise in the investigation of causes of failure of wind turbine components. This is performed in close cooperation with stakeholders from all areas of the value chain. The aim when doing so is to improve reliability and reduce both costs and the associated risks.

IWES has generated an extensive, continuously growing collection of field data from more than 10,000 wind turbines in projects. Thanks to its size, diversity, and up-to-dateness, this data set is unique and it spans a wide range of turbine age classes, manufacturers, and installation sites. On the basis of this data set, IWES supplies reliability data for OPEX modeling and cost-benefit analysis. In addition, IWES also offers solutions for early fault detection and conducts failure cause analyses.

Certification I Accreditation

Numerical yield and site assessment

Countermeasures against too intense vibrations: Identifying the susceptibility of rotor blades

When a turbine is at a standstill or fails, it can begin trundling. In turn, this can result in the wind reaching the rotor blades at very high angles of attack. This leads to vortex shedding, which triggers heavily alternating loads on the blades and can cause them to vibrate. Depending on the intensity of the vibrations, they can damage or even destroy the blade or the turbine. As there are no reliable models currently available for this process, IWES performs computational fluid dynamics (CFD) simulations on flexible rotor blades. This makes it possible to identify a rotor blade’s susceptibility to such vibrations in certain scenarios and implement countermeasures where appropriate.

Computational fluid dynamics (CFD) as a solution

Wind turbine rotor blades are currently designed to be slender and flexible. This has a range of advantages, including aerodynamic ones. One disadvantage is that the flexibility can result in the development of undesirable vibrations. In blade design, it is possible to determine and calculate the behavior of the rotor blades well for standard turbine operation. However, this is not the case if the flow behavior on the blades becomes highly unsteady, e.g., due to vortex shedding. This happens with high wind speeds or in cases where the turbine is not in operation or, in extreme cases, can no longer be controlled.

Computational fluid dynamics makes it possible to investigate precisely this problem with a physics-based approach to flow calculation. IWES has created the possibility of a flow structure-coupled simulation with the open source code OpenFoam. In this approach, non-linear beams are mapped for the structure on the basis of the geometrically exact beam theory (GEBT) in order to be able to visualize even large deformations with precision. This method makes it possible to analyze the blade vibrations in critical cases in detail and compare them with simplified model calculations.

Comprehensive expertise in wind turbine simulation

In the scope of OpenFoam, Fraunhofer IWES developed a comprehensive simulation setup for wind turbines, which is being continuously validated as part of the IEA Wind Task 47 and with data from the HighRe project. This makes it possible to include trundling turbines and the dynamic yawing of the turbines in the simulation. Independently of the vortex issue, it is also possible to integrate aerodynamic elements into the simulation, which contribute to improving the aerodynamics.

High-performance computing for wind energy

CFD calculations take a considerable amount of time. IWES utilizes its many years of expertise in the field of high-performance computing on appropriate computers to carry out the calculations in an optimized and efficient manner. The institute advises and trains companies in order to open up the possibilities of open source CFD for industry.

Post-construction analysis provides information on yield and performance

Post-construction analysis (PCA) provides operators and owners of wind turbines with important information on their energy yield and performance. In cooperation with partners in public and bilateral projects, IWES has compiled a representative data set of offshore wind farm data for the development of PCA methods.

The combination of wind farm yield data analyses with numerical methods and models makes it possible to consider the causes for the performance of a wind farm individually. In addition, a data set from numerical weather simulations is employed to take into account relevant parameters such as the calibration of models for wake calculation.

In fact, integrating the IWES’ methods makes it possible to answer a far larger number of questions. For example: How much would the wind farm actually have been able to generate during grid supply outages as well as during feed-in restrictions (feed-in management)? Or: What effects do neighboring farms have on the expected yield and can previous data already confirm this? The application of the methods results in greater certainty about the yield to be expected in the future compared to previous yield assessments.

IWES is constantly working on optimizing the range of PCA consulting services it offers the wind industry and pushing ahead with the standardization of the methods in an ongoing research project.

Certification I Accreditation

Wind farm optimization with Flow © Fraunhofer IWES

Offshore logistics

Project and risk management for offshore wind farms: minimizing costs and boosting efficiency

Efficient project and risk management forms the basis for the successful and cost-efficient planning, installation, and operation of offshore wind farms. In the planning and execution phase, IWES offers project plan and weather risk analyses for early identification and assessment of potential risks. Its expertise means that IWES can help to minimize risks and optimize the efficiency of the project logistics.

Post-construction and performance analyses allow assessment of the performance and efficiency of already installed offshore wind farms. IWES can then make suggestions for optimization on the basis of the results. With the conceptual design of maintenance concepts for offshore wind farms and the evaluation of existing concepts, IWES contributes to finding the optimal operating strategy for wind farms and minimizing costs.

In addition, IWES offers the optimization of the O&M logistics in order to render the operation and maintenance of the offshore wind farms more efficient. IWES analyzes the logistics processes and develops customized solutions for maximizing the availability of the turbines and optimizing the O&M costs.

Reducing the energy production costs of offshore wind farms with targeted strategies

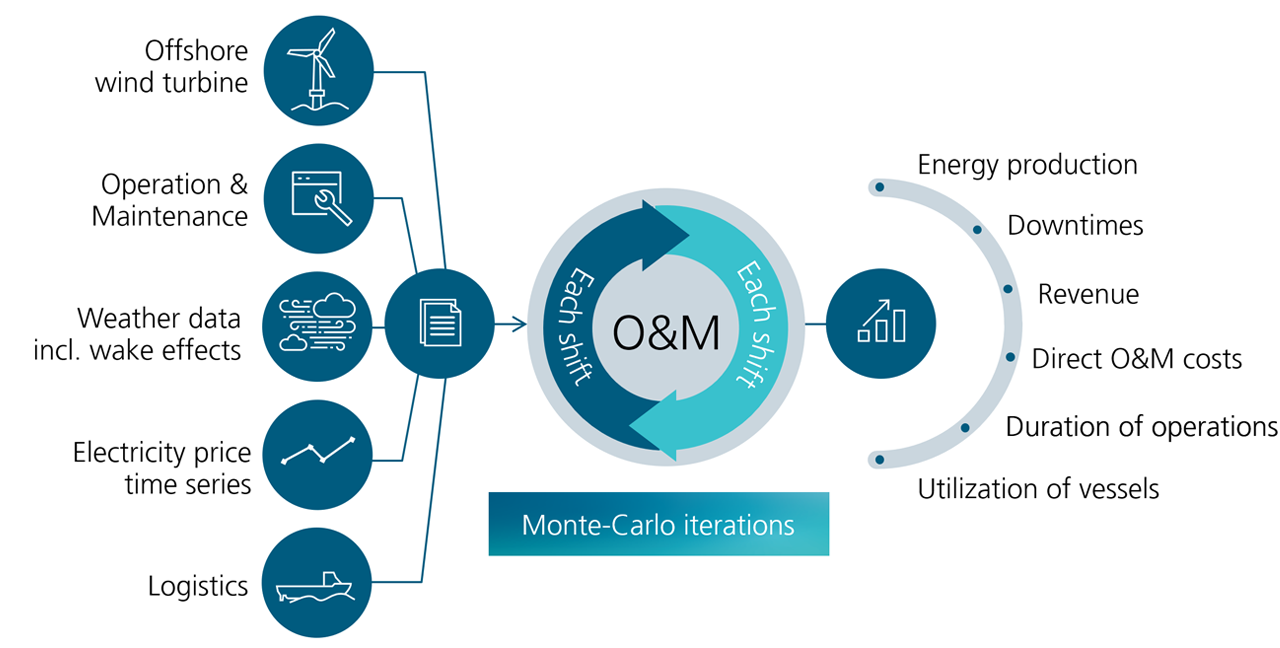

The installation and operating concepts of offshore wind farms are improved via the evaluation and development of concepts and future-oriented methods. This aim is achieved through the use of innovative in-house software tools, with which the installation and the entire life cycle of an offshore wind farm can be mapped and analyzed in detailed time series simulations.

The developed software tools identify potential problems and risks presenting during the installation and operation of an offshore wind farm, especially weather risks. IWES can then employ the knowledge gained to develop strategies for evaluating and analyzing these risks. Recommendations for action are then derived from these analyses, which contribute to optimizing offshore wind farms in terms of efficiency and costs.

The acquired knowledge of the installation and operating concepts and their associated risks for offshore wind farms can be utilized to reduce the farms’ energy production costs. In addition, the provision of extremely detailed simulations of offshore wind farms enables the software tools to deliver a wide range of other (key) performance indicators.

Certification I Accreditation