Analysis and modeling of operation and installation

Research in the analysis and modeling of installation, operations and maintenance at Fraunhofer IWES:

Field data-based analysis of failure causes and reliability modeling

Early fault detection and prediction of remaining useful life

Wind farms: Digitalization and standardization of operating and maintenance (O&M) data

Offshore project logistics: Time series-based analysis of weather risks

Offshore wind farms: Decision support for evaluation of maintenance concepts

From research to practice:

Our services in the analysis and modeling of operation and installation

Field data-based analysis of failure causes and reliability modeling

Wind turbine failures lead to considerable repair costs and yield losses. The reliability of turbines and their components – especially those with high failure rates – is thus of key importance for further reducing the levelized cost of electricity (LCOE).

Uncovering failure causes is therefore a focal point of our research and can inform improvements in component design, test procedures, and operational management. We also develop reliability models describing the failure behavior of the wind turbine components and mapping the influence of design aspects, operation, and environmental conditions to failure behavior.

To do so, we analyze failure, operating, and environmental climate data from wind farms all over the world. We utilize statistical methods and constantly develop them into more effective tools. In this way, the research contributes to improving the reliability and availability of wind turbines as well as, for example, developing cost-optimized maintenance strategies.

Early detection of faults and prediction of remaining service life

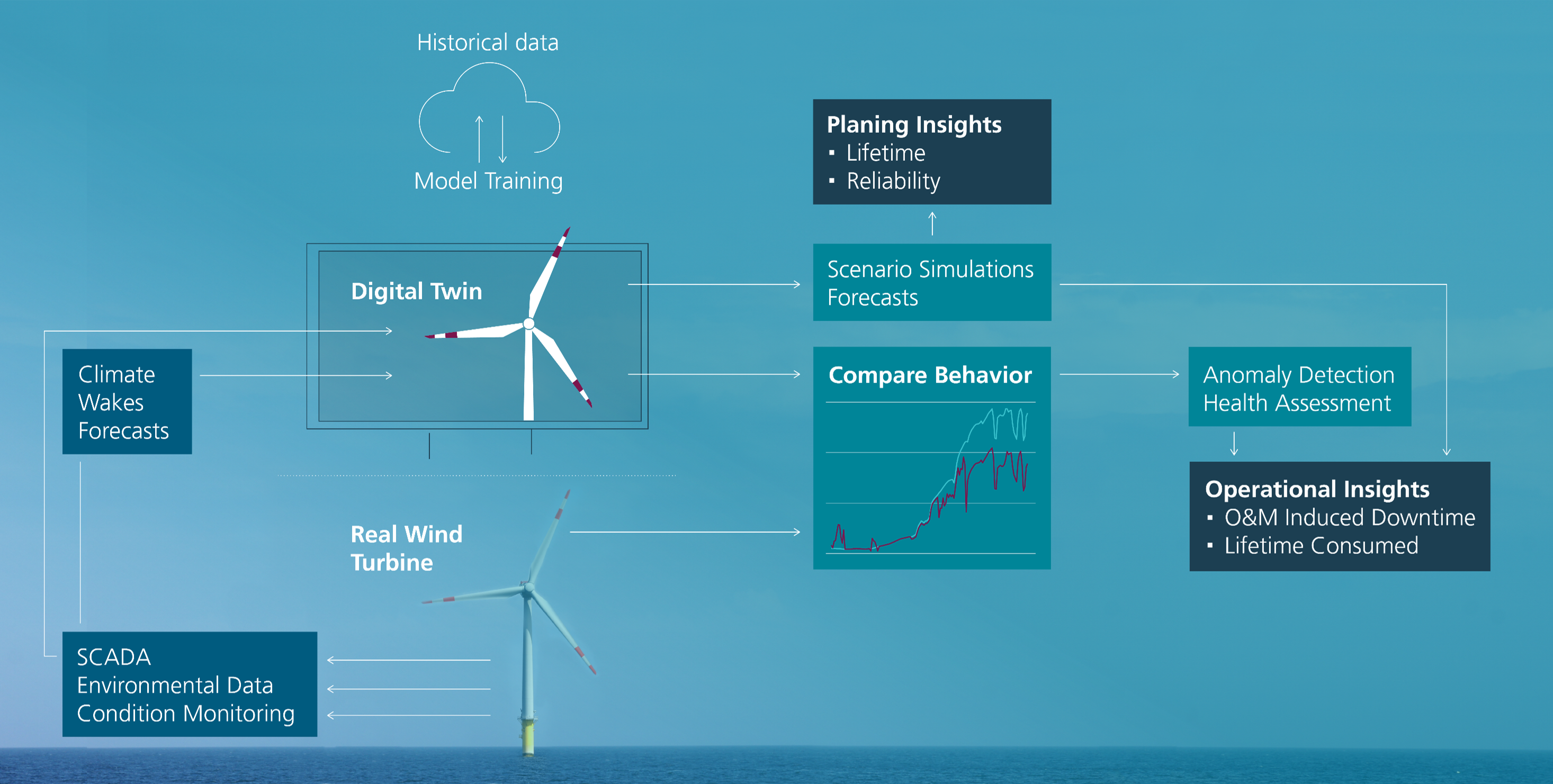

There are usually precursors to the failure of wind turbine components. The early detection of these precursors and implementation of preventative measures can help to avoid costly damage. In addition to reducing repair costs, continuous condition monitoring facilitates better planning of maintenance interventions, resulting in shorter downtimes and reduced revenue losses.

Some stakeholders complain that the monitoring systems currently in use provide inadequate reliability and detection performance. Furthermore, condition monitoring systems for some components associated with high repair costs such as frequency converters and rotor blade bearings are practically non-existent, meaning that their condition-based maintenance is not possible at present. At Fraunhofer IWES, we are working on measuring systems and processes to detect degradation and damage to even these turbine components at an early stage. We are also conducting research into the use of high-resolution operating data for early fault detection and diagnosis. The processes used range from physical-empirical models to fleet comparison to machine learning methods. If damage models are available, it is possible to predict the remaining useful life based on the historical component loads.

IWES’ research in this field contributes to condition-based maintenance, which helps prevent failures and permits the complete utilization of components’ lifetimes.

Wind farms: Digitalization and standardization of operating and maintenance (O&M) data

The cross-company evaluation of field data from the operation of wind farms offers the opportunity to identify the potential for cost savings. However, cross-company learning processes often fail at present, not due to a lack of data, but rather due to a lack of standardization and the companies’ fear of losing control over their data. For this reason, IWES is intensively involved in research into digitalization and standardization of operating and maintenance data from wind turbines as well as the development of data trust models. Among other things, research is being conducted into the semi-automated processing of maintenance data using text classification methods from the field of machine learning, which could help to considerably reduce the immense effort required for the manual processing by experts. IWES’ research in these fields is contributing to the further digitalization of the wind energy industry and supporting the development of data-based business models and innovative technologies.

Offshore project logistics: Time series-based analysis of weather risks

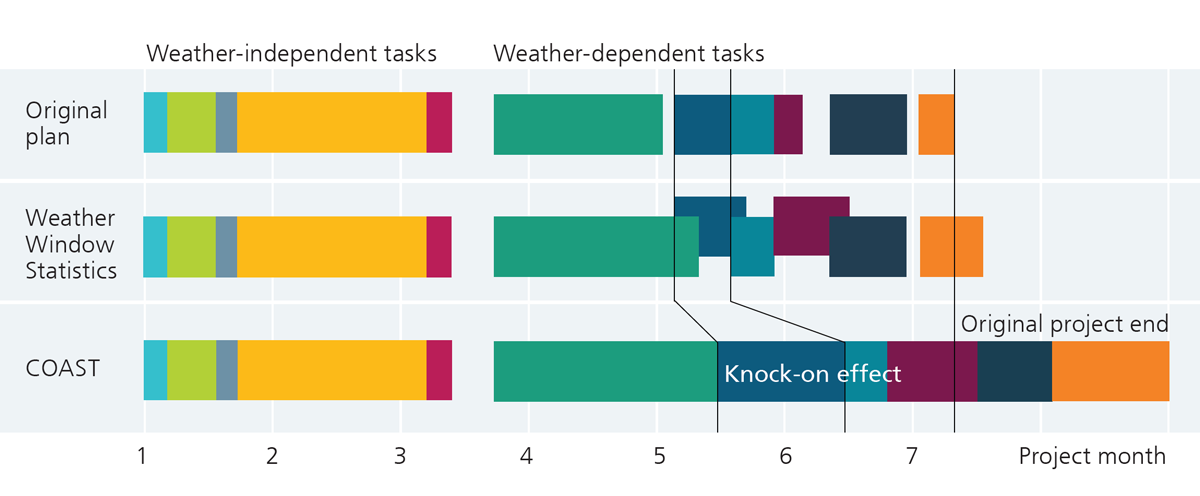

In offshore projects of any kind, the identification and analysis of risk profiles provide approaches for optimizing the life cycle costs and completing projects on time, on budget, and in accordance with quality standards. One aim of IWES’ research is to analyze and optimize the project logistics in the planning, execution, and decommissioning phases to reduce the weather risk and associated costs. The AdWaTSS (Advanced Weather Time Series Scheduling) method developed for this purpose simulates the sequence of offshore activities with their weather restrictions using a discrete-time approach. The method is based on weather time series spanning many years to realistically take weather-related delays into account. The results of the simulation are then statistically analyzed.

Considering multidimensional, direction-dependent weather restrictions and the distribution of weather risks throughout the project allows us to analyze any delays and their impact on subsequent milestones. This enables the identification of causes of knock-on effects if, for example, a task is not completed on time and subsequent tasks are delayed as a result. In addition, valuable conclusions can also be drawn for project planning.

Offshore wind farms: Decision support for evaluating maintenance concepts

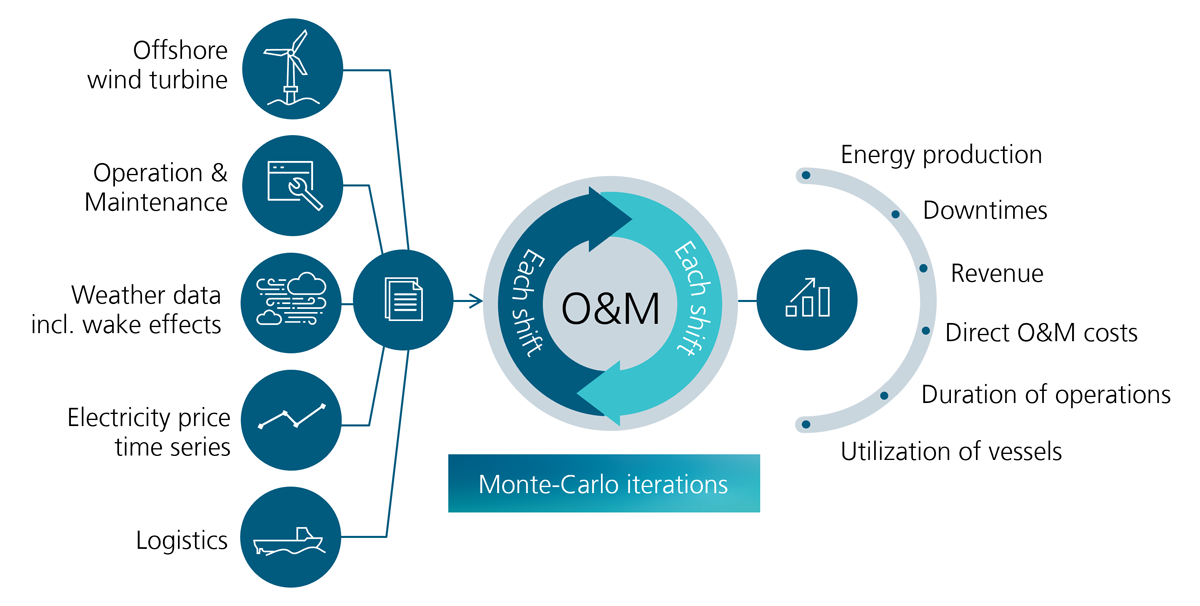

The harsh conditions of the high seas present a challenge for operations and maintenance (O&M) activities at offshore wind farms. A suitable maintenance strategy can make it possible to reduce costs considerably and maximize energy yield.

The use of agent-based decision support tools allows complex relationships and interactions between different factors to be considered. The agents are fed with information about resources, weather conditions, performance data, and other parameters. To this end, IWES is bundling its expertise and methods in yield assessment, reliability modeling, and marine logistics. The tool we are creating employs discrete-time Monte Carlo simulation to represent the O&M phase of an offshore wind farm. In addition to electricity price models, concepts for evaluating innovative maintenance strategies are also integrated. Results are generated for energy production, downtimes, direct O&M costs, duration of operations, use of deployed vessels, and revenue.

In addition, conclusions are drawn from historical service and repair work based on large amounts of data. For this purpose, AIS data, vessel-specific data, and data on helicopter movements are merged with operating and weather data. The evaluation is performed using a combination of deterministic analysis methods and AI approaches for pattern recognition. In this way, the performance of logistics processes can be evaluated and improved.

Probabilistic cost modeling of offshore wind farm projects

Offshore wind energy is set to play a prominent role in meeting future energy needs in Germany, Europe, and the world. Although significant progress in cost reduction has already been achieved in the last decade, the installation and operating costs are still considerable and vary in the individual markets. Fraunhofer IWES designs and creates probabilistic levelized cost of energy (LCOE) models. They are an important provider of key performance indicators (KPI) for the cost- and energy yield-based assessment of the technology. Offshore wind projects are subject to complex uncertainties such as the availability of wind resources, weather influences, the accessibility and availability of assets, the turbine performance, and losses during energy production. The accuracy of the LCOE estimates influences the return on investment (ROI) of a wind farm project. A probabilistic LCOE model takes these uncertainties into consideration when calculating costs and forms a new, holistic approach for a combined, advanced cost and risk assessment. This provides a basis for making projects and PPAs competitive, in questions relating to the refinancing of wind farms, or for the economic evaluation of possible continued operation.