Virtual test rigs

Research in the field of Virtual test rigs at Fraunhofer IWES:

Virtual test rigs: virtual testing for reliable forecasts

Rapid, cost-efficient, reliable: The testing of offshore support structures on the digital twin

From research to practice:

Virtual test rigs: virtual testing for reliable forecasts

At IWES, virtual testing is part of physical testing. It is primarily used for the precise and efficient realization of conventional tests and the development of innovative test methods. Using virtual test rigs and scaled large-scale tests, for example, IWES is able to precisely analyze even extremely large components such as support structures for wind turbines. Digital twins help to evaluate changes to the test geometry, the load or the geotechnical conditions quickly and cost-effectively.

Privacy warning

With the click on the play button an external video from www.youtube.com is loaded and started. Your data is possible transferred and stored to third party. Do not start the video if you disagree. Find more about the youtube privacy statement under the following link: https://policies.google.com/privacyNew test method: Biaxial rotor blade fatigue test

Virtual testing of rotor blades: Innovative test concepts such as biaxial fatigue testing and segment testing

Alongside the improvement of the conventional tests, the development of innovative new test concepts is another core element of the research conducted by the Virtual Testing group. In biaxial elliptical fatigue testing, the natural frequencies of a rotor blade in the flapwise and edgewise directions are adjusted via special test elements. On the test rig, this results in elliptical movements of the rotor blade. Combining two tests makes it possible to save a great deal of time and apply combined loads to the blade at the same time. This approach replicates the real-life loading situation far more reliably than in conventional testing, thus improving the quality of the validation and reducing failures in the field.

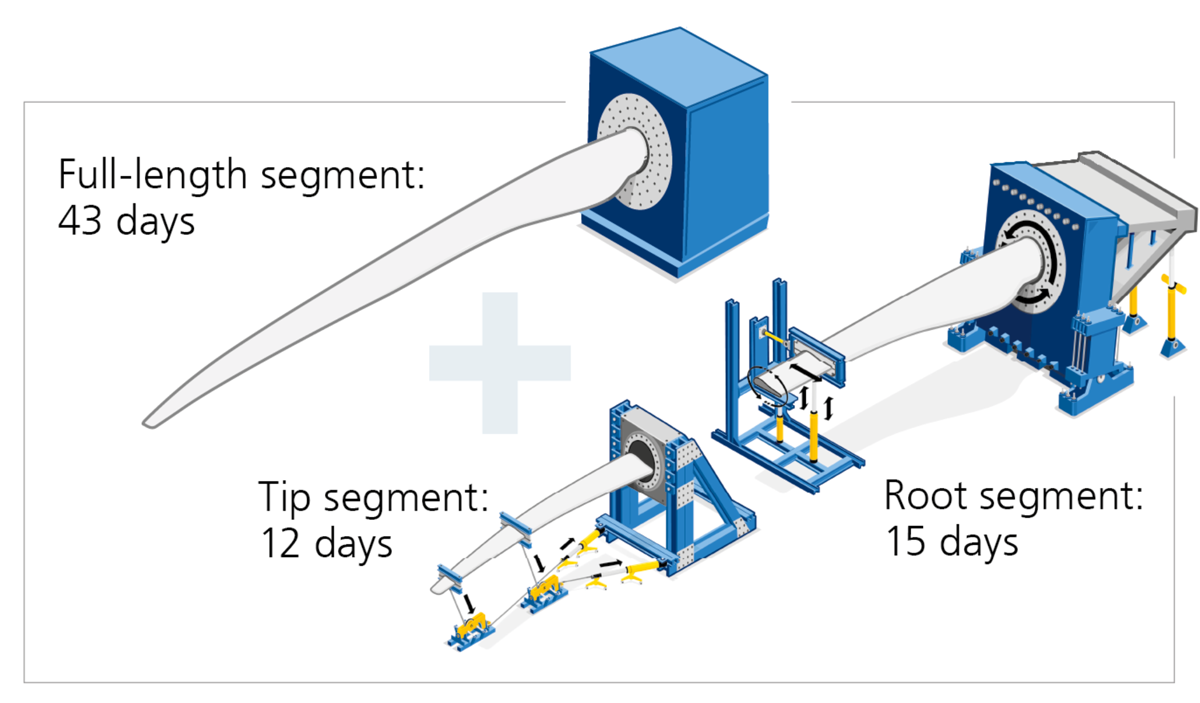

The testing of blade segments in different test sequences and the accumulation of induced damage until reaching the target damage is another test method which unites multiple advantages: On the one hand, the blade segments display comparably high natural and thus test frequencies, which can shorten test times by up to 50%, and, on the other, the damage of the individual sequences can be combined so precisely that the target damage can be induced homogeneously to the area of the rotor blade to be tested.

The experimental validation of rotor blades is an important aspect in the development of new rotor blade types. With rotor blades becoming ever larger, test campaigns are more complex and take longer. By precisely designing the fatigue tests, suitable test setups can be defined, and the tests can be carried out efficiently and reliably. The scientists have developed a design tool for this purpose. This enables a more precise prediction of the rotor blade behavior within the test environment. In this way, the required properties of test elements can be determined to set target parameters such as the target bending moment distribution and prevent the blade from being overloaded.

Rapid, cost-efficient, reliable: The testing of offshore support structures on the digital twin

Support structures for wind turbines are usually extremely large components, which cannot normally be mechanically tested on a 1:1 scale anymore in order to gain information regarding the life span or admissible maximum loads, for example. Nonetheless, IWES is pursuing a special research concept so as to be able to provide designers and operators with meaningful data and reliable models: (feasible) scaled large-scale tests, fully developed numerical and analytical methods, and measurement data from real systems are utilized together in a virtual test bench. The combination of intensively instrumented large-scale tests with real data allows the central, numerical core of the virtual test bench to be validated with high reliability. This produces a multifunctional tool for the support of development processes in the areas of foundations and support structures.

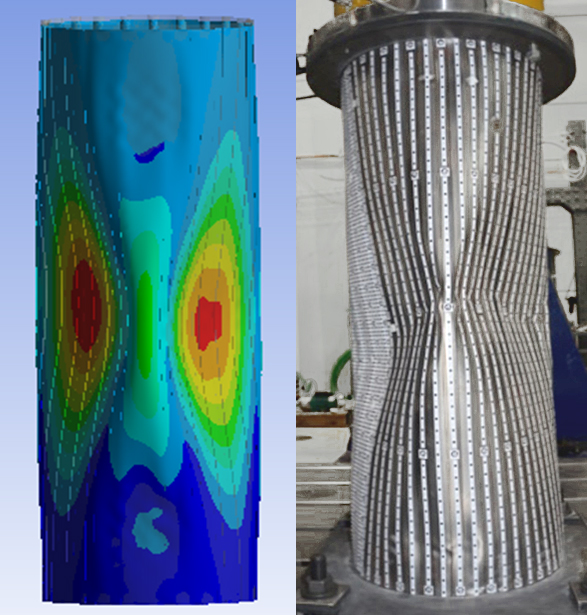

Simulation models are an integral part of the research and development work conducted at IWES. Digital twins help with the rapid and cost-efficient assessment of changes to the test geometry, loading, or even geotechnical conditions. In addition, the digital twin provides detailed virtual insights into the geotechnical test pit, which would otherwise only be possible at individual points using measuring sensors (earth pressure sensors, for example).

In combination, digital twins and large-scale tests can be used to investigate both existing and new foundation systems and installation methods and validate simulation models.

Digital twins help to minimize testing costs and times as well as increasing the quality of the results, particularly when the components being investigated are large-scale steel constructions: Digital twins can be used to assess changes to the test geometry (e.g., different wall thicknesses, local deformations due to transport damage) and thus optimize components according to their use, for example. State-of-the-art, robot-assisted image processing methods are in use at IWES for this purpose. This allows the simulation of real, imperfect (and not idealized) geometries on the one hand and makes information available on fatigue damage that cannot be detected by the naked eye or using conventional testing methods on the other. In combination, digital twins, large-scale tests, and image processing methods can be used to validate simulation models for fatigue and buckling failure.