System understanding for field data-based reliability modeling

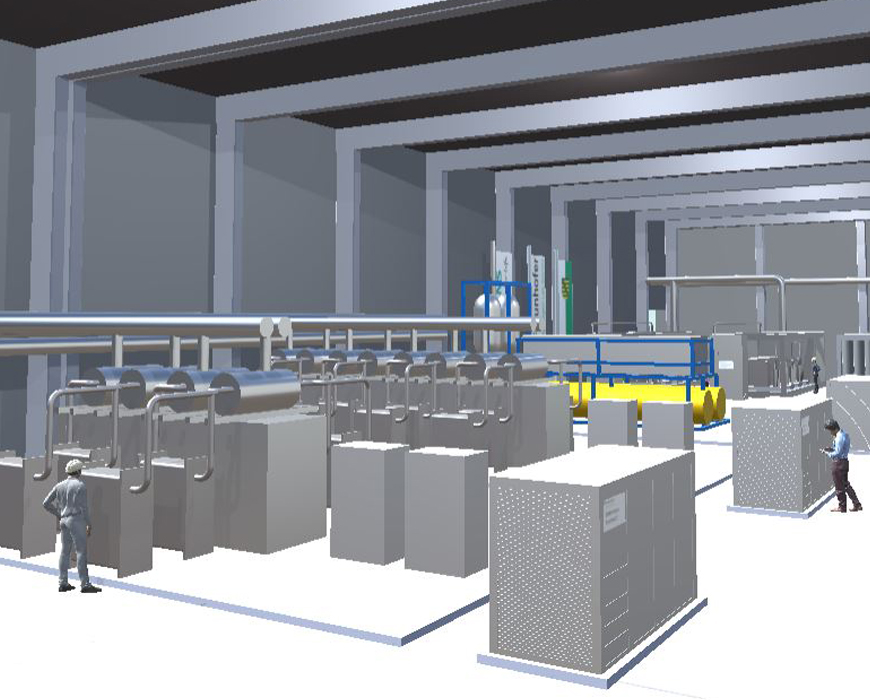

Fraunhofer IWES’ Directors have their offices at the Postkamp location in the heart of Hanover city. Research here focuses on the analysis of operating and maintenance data. One of the primary goals is to render components such as converters more reliable through testing, condition monitoring, and fault analysis.

Other areas of research also include early fault detection and predictive maintenance concepts. Projects on field data-based reliability modeling take the entire wind turbine system into consideration. Of course, components such as rotor blades and support structures also need to be further optimized – but always with the whole system in mind. The scientists are able to draw on data from more than 10,000 turbines for their work.

In addition, IWES teaches key skills regarding system understanding and interdisciplinarity in degree courses at the Leibniz University Hannover, where the students learn to understand the interactions between the wind, wind turbine, individual turbine components, and wide area synchronous grid (WASG) as well as between wind turbines themselves. The close cooperation offers them the opportunity to utilize the unique IWES test infrastructure from coupon to full-scale blade testing. More info: https://www.iwes.uni-hannover.de/en/institute

The site is also particularly characterized by the many collaborations with other Fraunhofer institutes. Key research projects include the Innovation Cluster Power Electronics, power4re (Reliable Power Converter for the Provision of Renewable Energy), and HiPE-LAB.

Download the fact sheet: Understanding and improving O&M activities

Our service portfolio here: Reliability, monitoring, and yield analysis, Electrical components and system validation