Large bearing test bench starts continuous operation

Fraunhofer´s test bench for rotor blade bearings of up to 6.5 meters in diameter has been successfully commissioned at the institute’s Hamburg facility, paving the way for automated continuous operation. Manufacturers and operators stand to benefit, as the accelerated tests – simulating 20 years of service in six months of testing – will enable them to increase the reliability of large rolling bearings and develop new calculation methods and designs. What’s more, a bearing can be validated on the test bench long before it is installed in a wind turbine, something never before possible in this manner. The aim is to lower development costs and reduce yield loss in order to make it more economical to operate wind turbines up to 10 MW.

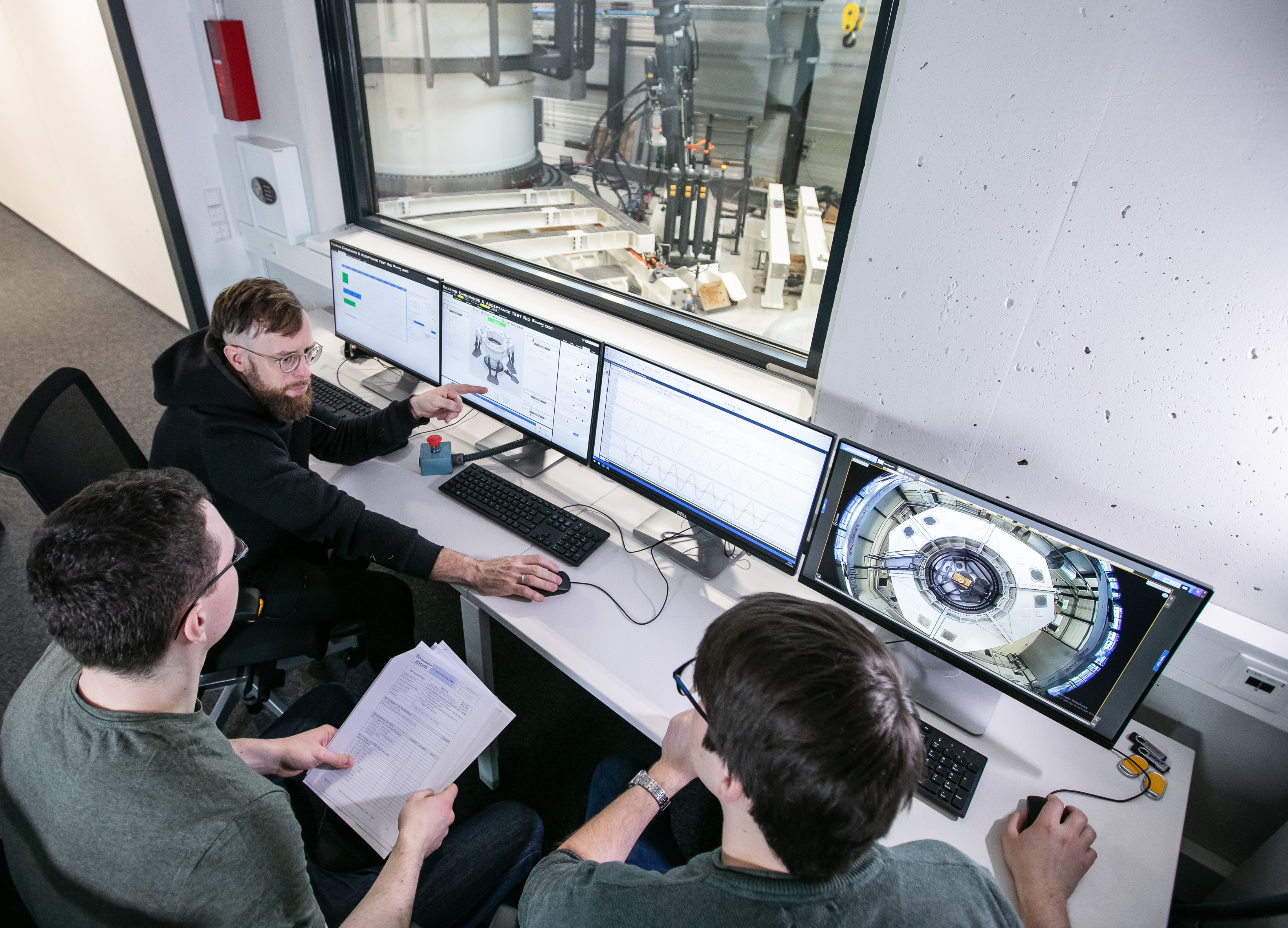

The noise of the seven hydraulic cylinders responsible for dynamic load application gives an impression of the force they transmit to the bearing. In laboratory testing they simulate rotor blade movement and rotor rotation during wind turbine operation, with all the load cycles that represent such an immense load on the rolling bearing. The cycle time of the main controller is one millisecond: the speed at which the human nervous system transmits signals. The commissioning phase was an exciting time for all involved. “This phase is the manifestation of the past five years of research work and we get to see how well the safety systems and the components interact”, explained Fraunhofer IWES´ Senior Engineer Matthias Stammler.

Failures well before the end of the calculated fatigue life are not unusual for wind turbine rolling bearings. At the moment, certification bodies do not require a service life calculation for such oscillating rolling bearings that connect rotor blade and rotor hub because current methods produce results with limited significance. Researchers at Fraunhofer IWES want to establish a sound basis: given a better understanding of what is happening early on in the process of damage, designs can be modified, design methods reviewed, and the risk of failure lessened. Comparing simulation data with measurement data makes a detailed fatigue lifetime calculation possible. Not only the bearing as a whole but also individual sections of the raceway are calculated to get more exact figures.

General contractor IDOM joint IWES for the entire construction, commissioning and acceptance. “We worked closely and intensely together with IWES during the last 18 months and we are now very proud to deliver this highly innovative test rig as a landmark for the future testing of the new offshore wind turbine blade bearings -combining very high static and dynamic load capacity, with superb accuracy and finely tuned boundary conditions emulation”, explained Operations Director Dr. Armando Bilbao.

From concept development through to simulation, design, testing, and, finally, diagnosis, the IWES portfolio covers the entire life cycle of a large rolling bearing. In addition to the BEAT 6.1 large bearing test bench, the institute operates other test rigs for rotor blade bearings and main bearings as well as smaller facilities for basic experiments and for testing large quantities.

The first significant test objects weigh around 9,500 kg each and are part of the HAPT (Highly Accelerated Pitch Bearing Test) research project funded by the German Federal Ministry for Economic Affairs and Energy (BMWi): eight bearings with a nominal diameter of five meters will undergo tests of function and fatigue between now and the summer 2021. This project in collaboration with the Institute of Machine Elements, Engineering Design and Tribology (IMKT) of Leibniz University Hannover and the IMO Group aims to develop methods for the accelerated testing of rotor blade bearings.

The Large Bearing Laboratory (LBL) at the institute’s Hamburg facility bundles activities and additionally offers experimental testing facilities for next-generation wind turbine bearings. This test bench expands Fraunhofer IWES’ portfolio of validation services, which, in turn, help turbine and component manufacturers to safeguard further and new developments prior to their market launch.

Technical data:

- Testing of bearings of 3 to 6.5 m in diameter

- Application of static loads of up to 50 MNm

- Dynamic bending moments of +/- 25 MNm at 0.7 Hz

- Highly integrated monitoring and data capturing system with very high processing speeds – self-sufficient operation for months

- Measuring system with 500 high-resolution measurement channels and redundant databases

- Emulation of attachments and their properties

Last modified: